R&D

Research & Development is getting your sensors to meet customer specs. R&D is actually one of the easier pieces of Capsim. You start out with 5 sensors, each in a different market segment. You already know how far to advance the design each year, based on the customer's expectations and the information found in the Industry Report from Round 0.

Each sensor resides in a particular market segment. Some may end up with overlap, but you must target your products to a specific segment. Customers in each segment has 4 ranked buying criteria: Age, Positioning, Price and Reliability (MTBF)

Your R&D person directly controls 3 of the 4 criteria (pricing is set by marketing), and would work together with marketing and production to create ideal sensors that meet customer criteria.

Age is the customer's perceived age of the product. When a product is revised in R&D, the perceived age of that product is halved.

Positioning Costs

Your products are positioned within the perceptual map. Each segment has a fine cut and rough cut. Of course, you want R&D to keep up with movement of the perceptual map. The map moves every month, so the product can reside in the ideal position for only 1 of the 12 months in the year. However, when your product is within 0.5 of the ideal position, sales will not be affected. Keep in mind this monthly drift when planning your R&D positioning.

You can easily make a spreadsheet that positions your products to 1/2 or 1/3 behind the ideal; positioning your products there will save positioning costs and you'll not lose sales (unless your product is in the rough cut)

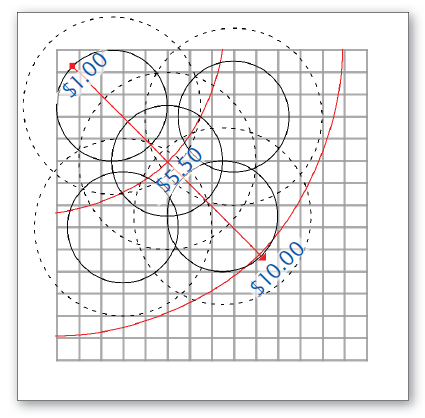

Positioning costs range from $1 at the trailing edge of the perceptual map up to $10 at the leading edge of the map. Costs along the arc in the middle are about $5.50. When the circles move, the costs remain the same.

COMMON MISTAKE: I see this every term in class - a team will R&D the low-end product backward in round 1 decisions because they confuse offset with drift. We recommend you leave low-end R&D alone in round 1.

MTBF ratings directly affect material costs, so you should check the MTBF ratings of each product against the Customer Buying Criteria on each segment analysis in the Courier. Check to see if they are higher than they need to be. If the MTBF range is 12,000 to 17,000, and it is the #4 buying criteria (Low End Segment), there is no benefit in having MTBF set higher than 12,000. Likewise, if a high tech product has reliability as the customer's #1 expectation, set MTBF to the top of the range.

Each 1,000 hours of MTBF will cost you $0.30 in materials.

Positioning and price criteria change every year. Age and MTBF criteria remain the same for the entire 8 rounds.

Each segment ranks their expectations differently. Pay close attention to the top 2 customer criteria, the other 2 are not as important.

Always keep your products inside the MTBF fine cut. Setting MTBF outside the fine cut will cost you 20% of your customer score for every 1,000 hours below the fine cut. Customers are indifferent to MTBF above the fine cut range. If you do it, you are wasting money. A product with 1,000 hours above the fine cut will cost an additional 30 cents per piece, affecting your margins (and profits)

If you set the MTBF reliability specs properly in round 1, you'll never have to adjust them for the remainder of the sim.

No comments:

Post a Comment

Note: Only a member of this blog may post a comment.